UV Printer vs Solvent Printer

Choosing the right industrial printing technology depends on many factors – from the type of material and the costs of printing to productivity. Two popular technologies that are often compared in the context of production are UV LED printing and solvent printing. In this article, we take a closer look at the differences between the two, focusing on Aquila UV LED and Aquila Nanosolvent printers to help you make an informed decision.

The principle of UV printing and nano-solvent printing

UV LED print uses UV-fixed inks, which allows prints to dry quickly and enables printing on a wide range of materials, including unusual ones such as glass and wood. By using UV light, the inks are instantly hardened, resulting in high durability and quality prints.

Nanosolvent prints are based on the use of solvent inks that penetrate the material and gradually evaporate, leaving a permanent image. This technology is particularly popular for printing on anodized aluminum.

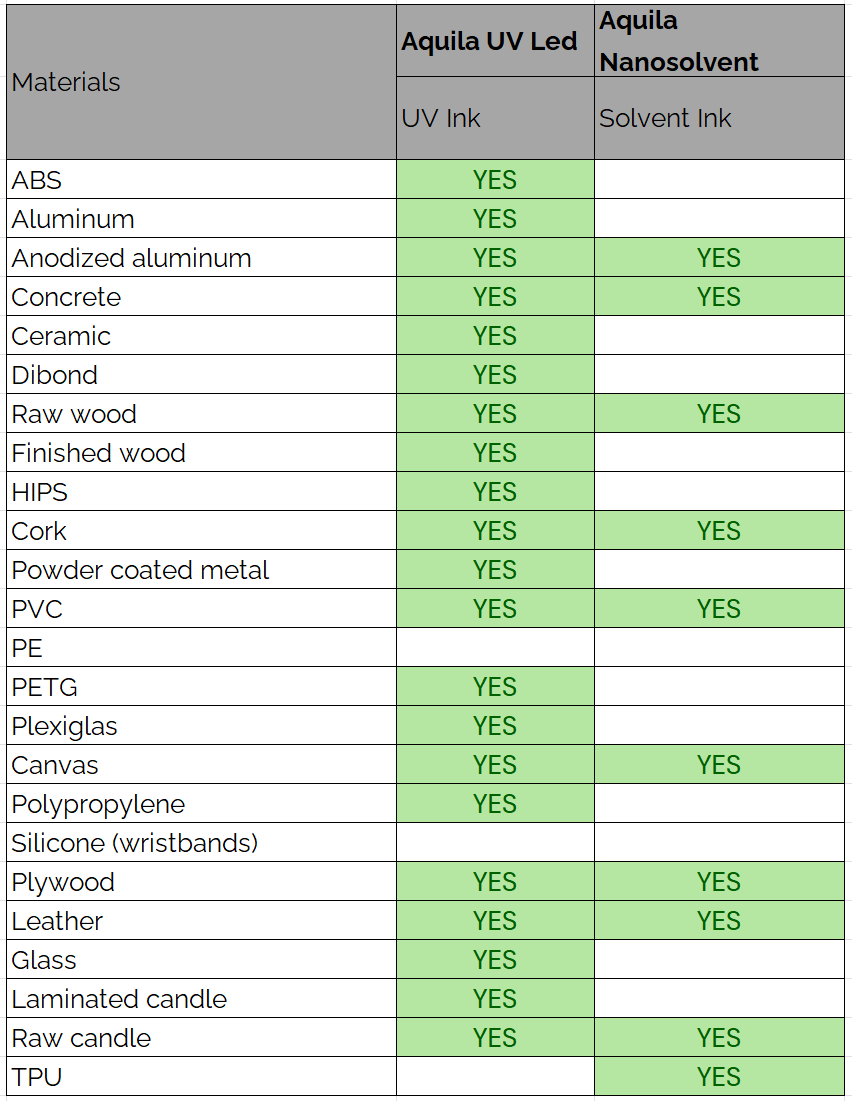

Surfaces and materials for printing

The variety of substrates that can be printed on is one of the key elements in choosing a technology. Here’s a look at the capabilities of the Aquila UV LED and Aquila Nanosolvent printers:

The UV LED printer has a wider range of applications, allowing printing on more diverse surfaces. Importantly, UV printing offers white ink, making it possible to print on materials that require an undercoat, such as transparent or dark surfaces.

It is also worth noting the possibility of printing on non-porous surfaces, such as glass or ceramics, where solvent printing will not work.

Durability and print quality

One of the key factors in choosing a printer is the quality of the print and its durability on various substrates.

UV LED printers are characterized by durability and precision printing. Thanks to instant curing, you can get crisp colors and sharp details even on uneven surfaces.

Nanosolvent ink, thanks to its penetration into the pores of the material, offers non-abrasive printing. An additional advantage of this process is the preservation of the original structure of the printed material, such as wood grain. Such an effect is impossible with UV LED printing, as the surface under the print is completely covered. So, as you can see, the two technologies differ significantly, so it’s worth considering what effect we expect.

It is worth mentioning that nano-solvent ink can be used for printing in Anodized Aluminum. This is a special technology that requires subsequent metal processing in addition to printing on the Aquila Aluminum printer. Thanks to the appropriate process, graphics made on anodized aluminum are resistant to mechanical and chemical damage, as well as high temperatures.

Therefore, if you are interested in printing, for example, nameplates, it is worthwhile to get acquainted with the Aquila Aluminum technology package. Permanent printing of aluminum sheets with solvent technology requires the use of special anodized aluminum. After finishing the print, the plates should be put into a bath of hot water, where the pores of the aluminum will seal. The whole process guarantees extraordinary durability, but consumes additional time.

Operating costs and efficiency

Printing costs are often the deciding factor in choosing a technology. Here’s how the printing costs for both printers compare:

Aquila UV LED = 1 EUR (320×650 mm, full color including white backing)

Aquila Nanosolvent = 0,1 EUR (320×500 mm, full color)

This comparison shows that Solvent printing is cheaper in terms of the cost of consumables alone. However, without printing a white backing for UV LED printing, these costs will be similar.

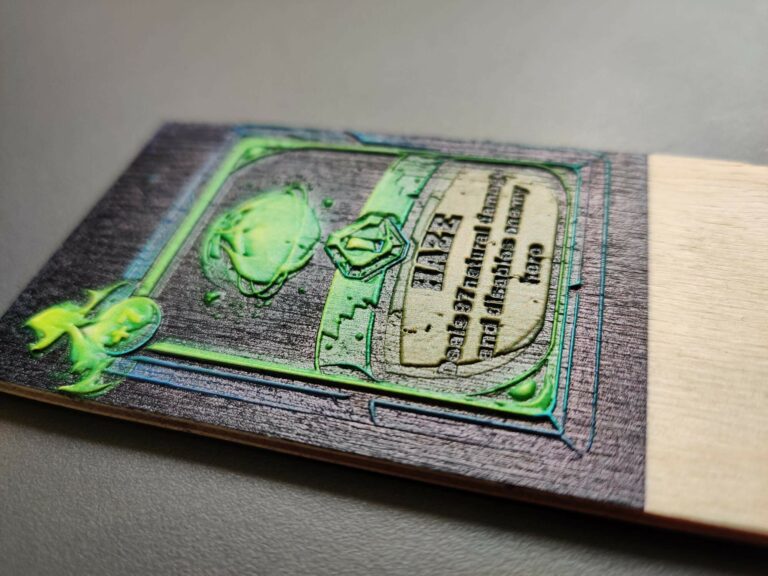

Imprint structure

The advantage of nano-solvent ink is “flat” printing. Once the dyes have soaked into the material, the print is undetectable “under the finger”.

On the other hand, UV printing is convex. You can take advantage of this by printing multiple layers on top of each other. Graphics created this way will gain texture and depth. This technique can be used, for example, when creating tiflomaps or parts for board games.

The fact that solvent printing soaks into the material also gives it an advantage over UV LED printing in terms of the print’s resistance to material bending. Solvent prints are flexible and deform with the substrate on which it is made.

Which technology to choose? Summary

Choosing the right printer depends largely on your needs:

- If you are printing on the specific materials (such as Aluminum) and care about the durability of the print, Aquila Nanosolvent or Aquila Aluminum (aluminum printing kit) will be an excellent choice.

- On the other hand, if you need versatility, printing on difficult surfaces (such as glass), Aquila UV LED is worth considering.

Both technologies, UV LED and solvent, have their advantages and disadvantages. UV LED printing provides greater flexibility for printing on a wide range of materials, while solvent printing is focused on more niche applications. Depending on your requirements, it’s worth considering which technology better suits your production needs.