7 Uses for UV Printers

UV printers have revolutionized the approach to printing on a variety of materials. UV LED technology allows the ink to cure instantly with ultraviolet light, resulting in durable and resistant prints on almost any surface – from wood to metal, glass and plastics.

Compared to traditional printing techniques, UV printers offer not only greater precision, but also a greener solution, eliminating the need for solvents and reducing energy consumption. In this article, we will take a look at how versatile this technology can be, especially in the context of applications in various industries.

UV Printer for gadgets

Printing promotional gadgets is one of the key areas where UV technology is gaining popularity. With UV printers, a wide range of products can be personalized, such as:

- Powerbanks: permanent company logo on the surface of the device.

- Phone cases: full-color prints that retain clarity and do not rub off.

- Pens and key rings: ideal for quick personalization on large orders.

And these are just some of the possible applications! UV technology works great here because it allows printing on irregularly shaped surfaces, ensuring precision even with small parts. Unlike traditional methods, there is no need to prepare special dies or molds, which significantly reduces turnaround time.

Benefits:

- Fast production even with small runs.

- Durable prints resistant to scratching and fading.

- The ability to print on materials of different textures and shapes.

UV printer for wood

UV printing on wood is becoming increasingly popular, especially in the interior design and furniture industries. Wood, as a natural material, is an ideal substrate for printing, which can add a unique character to it.

- Furniture: UV printing allows you to personalize your furniture by adding decorative patterns, logos or textures that are resistant to mechanical damage.

- Decorations and frames: artistic prints on photo frames or decorative wooden boxes are popular in the premium segment.

UV technology provides the ability to print on various types of wood, both raw and varnished. Importantly, the print is instantly cured, eliminating the problem of long ink drying time known from traditional methods.

Benefits:

- Precise printing on irregular surfaces.

- High resistance to mechanical damage and moisture.

- Ideal for personalization in the premium segment.

UV printer for glass

Printing on glass is another area where UV technology wins out over traditional printing methods. By using white inks as a base, prints on glass are crisp and reproduce the original colors well.

- Bottles and utility glassware: personalization of bottles, glasses or goblets can be an excellent marketing solution, such as for the premium liquor industry.

- Decorative panels: printed glass panels used in interior design are a modern way to give a room a unique character.

UV printing on glass is not only aesthetically pleasing, but also functional. The prints are scratch-resistant, making them ideal for use in areas subject to heavy use.

Benefits:

- Durability and resistance to scratches and moisture.

- The ability to create both transparent and colored prints.

- Applications in advertising, interior decoration and commercial production.

UV printer for metal and aluminum

Metal surfaces, such as aluminum, are difficult substrates for traditional printing methods, but UV technology handles it well. UV printing on metals offers precise detail reproduction, which is especially important for products such as:

- Personalized gift boxes: printing on aluminum is resistant to external factors, making it ideal for the wedding industry, for example.

- Medals, key rings and decorative items: personalization of metal products for souvenirs or promotions.

With the ability to print on hard and rigid materials, UV printers are invaluable in industries where the durability of prints is crucial.

Benefits:

- High print resistance.

- Ideal for printing on smooth and textured metal surfaces.

- Versatile application in many industries.

UV printer for ceramics

Ceramics, like glass, require specialized printing techniques to ensure the durability of the graphics on the surface. UV printers excel at printing on ceramics, offering unique capabilities:

- Mugs, plates and tiles: personalization of dishes and trim is becoming increasingly popular among both promotional companies and decorative element manufacturers.

UV printing on ceramics is resistant to washing, making it a perfect solution for the food service industry. The technology allows the creation of both full-color graphics and minimalist designs.

Thanks to the use of a special printing technique, we are able to obtain a unique printing structure.

Benefits:

- Resistant to washing and high temperatures.

- Ability to print on irregular surfaces, such as rounded surfaces.

- Attractive solutions in the catering and decorating industry.

UV printer for plastics

Plastics, such as PVC, ABS, Plexiglas and polycarbonate, are commonly used in the production of packaging, labels and banners. UV printing offers the ability to print precisely on these materials, which is crucial in many industries:

- Labels and packaging: permanent printing on films used in the packaging of food, cosmetic and industrial products.

- Advertising banners: the ability to print on large areas that are UV and weather resistant.

UV technology makes it possible to quickly apply prints to plastics without the risk of deformation under high temperatures, which is sometimes a problem with traditional printing methods.

Benefits:

- Durable prints resistant to UV rays and weather conditions.

- Versatile use in advertising, packaging and construction industries.

UV printer for DTF film

Direct to Film (DTF) technology is a modern method that allows printing on films, which can then be transferred to textiles. UV printing on DTF film is distinguished by its special flexibility and durability, making the prints resistant to repeated washing and heavy use.

- Advertising and personalized apparel: DTF film allows you to create detailed prints on T-shirts, caps and other textiles.

- Personalized stickers: the ability to easily create stickers that can then be applied to any surface.

The use of UV printing on DTF film is an excellent solution for apparel and advertising companies that want to introduce new, permanent printing methods on textiles. UV printing provides crisp colors and high resolution, which is crucial for personalizing garments.

Benefits:

- Resistance of prints to washing and heavy use.

- Ability to create detailed high-resolution graphics.

- Flexibility and durability of prints.

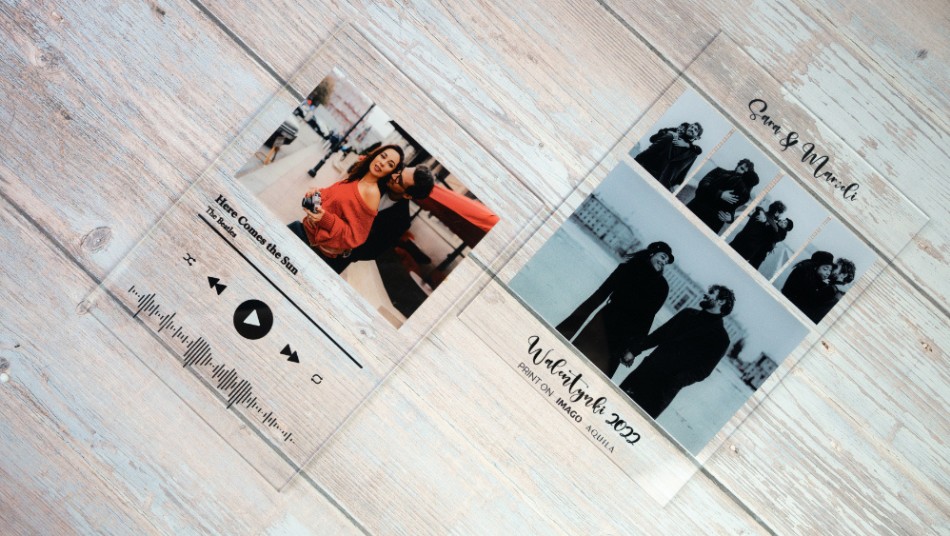

Why choose a UV LED Printer from IMAGO?

IMAGO offers small-format UV printers that adapt to the needs of even the most demanding users. Aquila UV LED stands out for its performance, reliability and ease of use. They are devices that can be used in a variety of industries such as the production of advertising gadgets.

Advantages of UV LED printer from IMAGO:

- High quality prints.

- Simple and intuitive operation.

- Efficient service.

- Possibility of direct printing even on irregular and round shapes.

Summary

UV technology is the perfect solution for companies that want to stand out in the market by offering unique and durable products. UV printers allow personalization of gadgets, home decoration, clothing and many other items, offering exceptional precision and resistance of prints. If you are looking for a printer that can meet all your printing needs on a variety of materials, UV Printer is for you.