Matrices – reliable acceleration of serial production

Matrices

Do you mark a lot of small products? Your production is repetitive? Matrices are the ideal solution for you. They facilitate the positioning of small products, eliminate the risk of error and speed up work in mass production.

Compatible with:

See how matrices can improve the work of the IMAGO printer

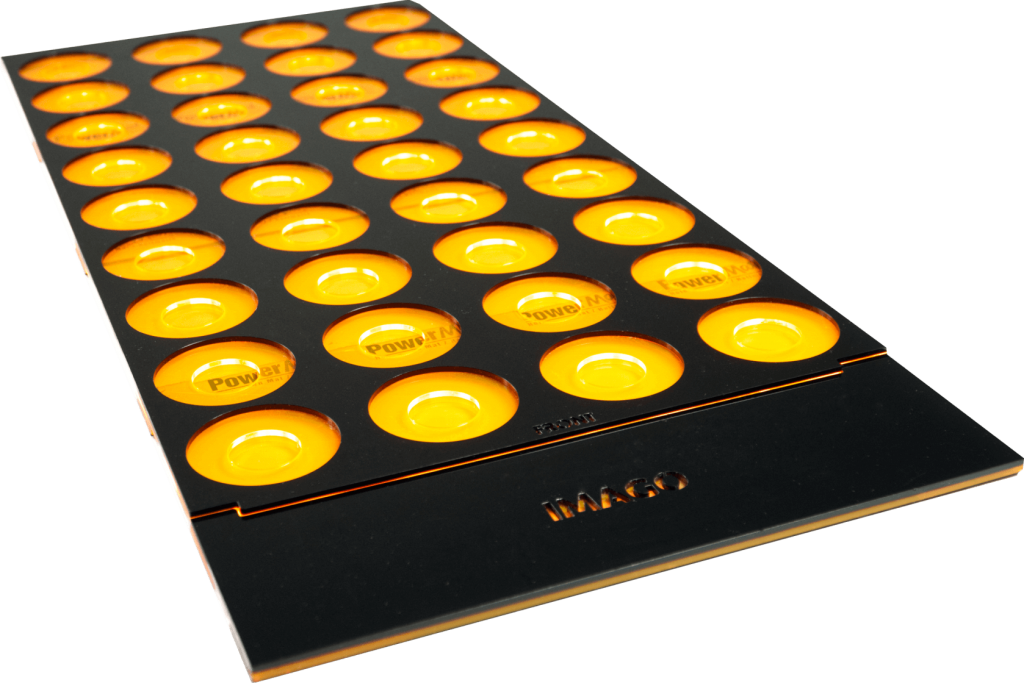

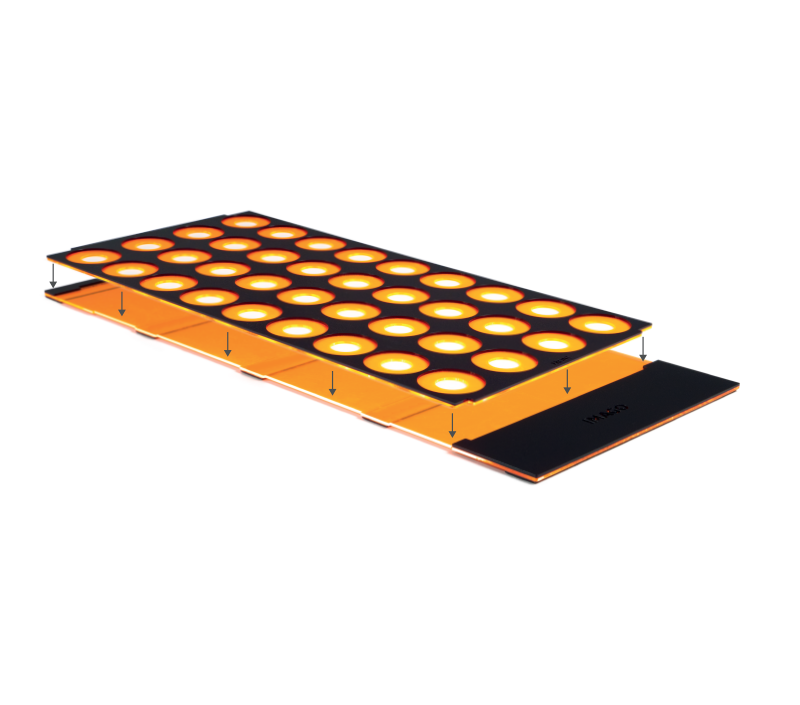

Construction of IMAGO matrices

Our dies are made in the convention of Japanese Poka-Yoke production management. The tool consists of two components: a base and a top, interchangeable part. Products are placed on the top part, which is adapted to a specific shape. The top part of the die can only be placed in one direction, avoiding costly mistakes and wasted time on product corrections.

Matrices tailored to your product

We make the tools to individual customer orders to match the chosen product. The matrices are adapted to the workbenches of IMAGO digital printers. This makes their installation quick and easy. A graphic file is also created for each matrix, which reproduces its shape. This makes it easier to apply graphics to a batch of product on the computer. The photographic quality of the image, attention to detail, precision and repeatability of the print will make your company’s work easier and faster.

Accelerate mass production on UV LED printer

The matrices streamline work and significantly reduce the lead time of batches of products. They facilitate the positioning of advertising gadgets, pens or small products with specific shapes.

Food matrices and printers

As with UV LED printers, we also create custom dies for food plotters. They make the work easier and speed up the decoration process. The tool works best when printing a large number of small products. For example, up to 900 macarons can be decorated in one hour. All you need for this is one base and a variable top part in the shape of your product.

The benefits to your business of having IMAGO matrices

Matrix tailored to your products

We design dies only for individual customer orders.

Easier positioning

Influencing the reduction of production losses due to misprinting.

Faster production

Automatic positioning of products on the table means fewer errors, resulting in more efficient production.

Shorter employee training time

Reduced training time for employees related to machine operation.

Full control of processes

Save time and increase operator productivity

During printing, it can prepare the next batch of products.

Accessories Matrices