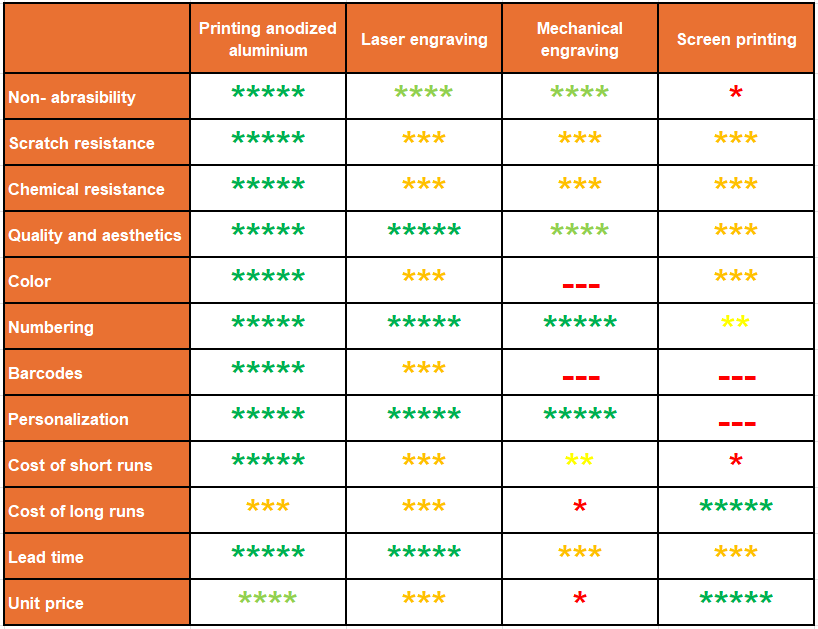

How to Choose a Printer for Nameplates? Comparison of different technologies

Nameplates play an extremely important role in industry – they provide essential information about equipment, machinery and products. On them we can find data such as model, serial number, technical parameters or certificates. Since the plates are often exposed to harsh working conditions – high temperatures, chemicals or UV radiation – they must be durable and legible for many years. Therefore, choosing the right printing technology is crucial. In this article, we’ll compare different methods for creating nameplates and show you which one is best for your company.

Popular technologies for creating nameplates

There are several methods of manufacturing nameplates on the market, which vary in terms of materials, durability and cost. Let’s take a look at the most popular technologies:

- Mechanical engraving

- It is one of the oldest and most traditional methods. It involves the mechanical removal of material from the surface of the plate, which creates permanent markings.

- Pros: exceptional durability, resistance to mechanical damage.

- Cons: Limited number of colors, less aesthetics and legibility compared to modern printing methods.

- Laser engraving

- This technology uses a laser to engrave or mark the surface of the plaque. Lasers can work on a variety of materials, such as metal, plastic and wood.

- Pros: Accurate and fast manufacturing, personalization possible.

- Cons: limited resistance to external factors for some materials.

- Nano-solvent printing

- Nanosolvent printing is a modern technology in which a special ink permanently penetrates into the molecules of a given surface. It is particularly effective for anodized aluminum, which works perfectly with this type of printing.

- Pros: exceptional durability, rich colors, resistance to chemicals and high temperatures.

- Cons: Requires specialized printers.

- Screen printing

- Screen printing is a method in which ink is passed through a special mesh (screen) and is applied directly to the surface of the nameplate. This technology is widely used for printing on various materials, including aluminum.

- Pros: considerable printing strength, the ability to apply thick layers of ink, as well as rich colors and high print durability.

- Cons: Limited precision compared to nanosolvent printing, especially for small details, and the need to make stencils, which significantly increases costs for small production runs.

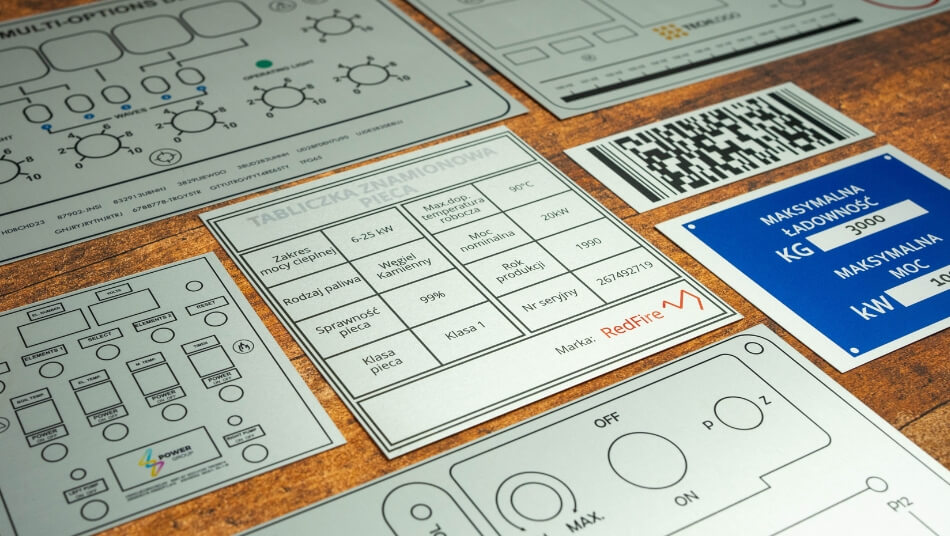

Anodized aluminum nameplates

One of the most durable and aesthetically pleasing solutions on the market are nameplates made of anodized aluminum, printed with nanosolvent technology. Why does this method stand out from others?

- Durability and resilience

- Anodized aluminum is not only lightweight, but also extremely durable. Thanks to the reverse anodizing process, an additional layer is formed on the print, which increases its resistance to corrosion and mechanical damage. Combined with nano-solvent printing, we get plates that are resistant to abrasion, moisture, chemicals and high temperatures, making them ideal for use in harsh industrial environments.

- Aesthetics and precision

- Nanosolvent printing makes it possible to achieve extremely precise and clear markings. With this technology, any graphic, logo or text can be applied to the plate, while maintaining full color and sharp detail. This is especially important for plaques that are intended to be not only functional, but also aesthetically pleasing.

- Economy and efficiency

- Nanosolvent printing is not only economical to operate, but also enables the production of high-quality prints with minimal consumption of consumables. Compared to other technologies, nano-solvent printers such as AQUILA Aluminum offer fast production rates, allowing orders to be completed in a short period of time. In addition, the technology does not require complex prepress, making it effective even for small print runs, while providing excellent quality and precision detail.

Why choose a Printer for Nameplates from IMAGO?

IMAGO is a company that offers advanced industrial printers, including models that specialize in printing nameplates from anodized aluminum using nano-solvent technology. What sets IMAGO printers apart?

- Advanced printing technology: our printers use the latest technological advances, ensuring the highest quality and durability of printing.

- Technical support: IMAGO offers full technical support, both for the installation of the device and its subsequent operation.

- Customized Approach: With flexible solutions, our printers can be customized to meet the specific needs of each customer, allowing for optimal adaptation to a variety of applications.

- Ease of use: Intuitive software and signaling systems simplify daily operations by informing the user when maintenance is needed, reducing the risk of downtime and extending equipment life.

Summary

Choosing the right printer for nameplates depends on a number of factors, such as the material you want to print on and the conditions in which they will be used. If you want durability, aesthetics and resistance to harsh industrial conditions, IMAGO nano-solvent printers for aluminum are the perfect solution.