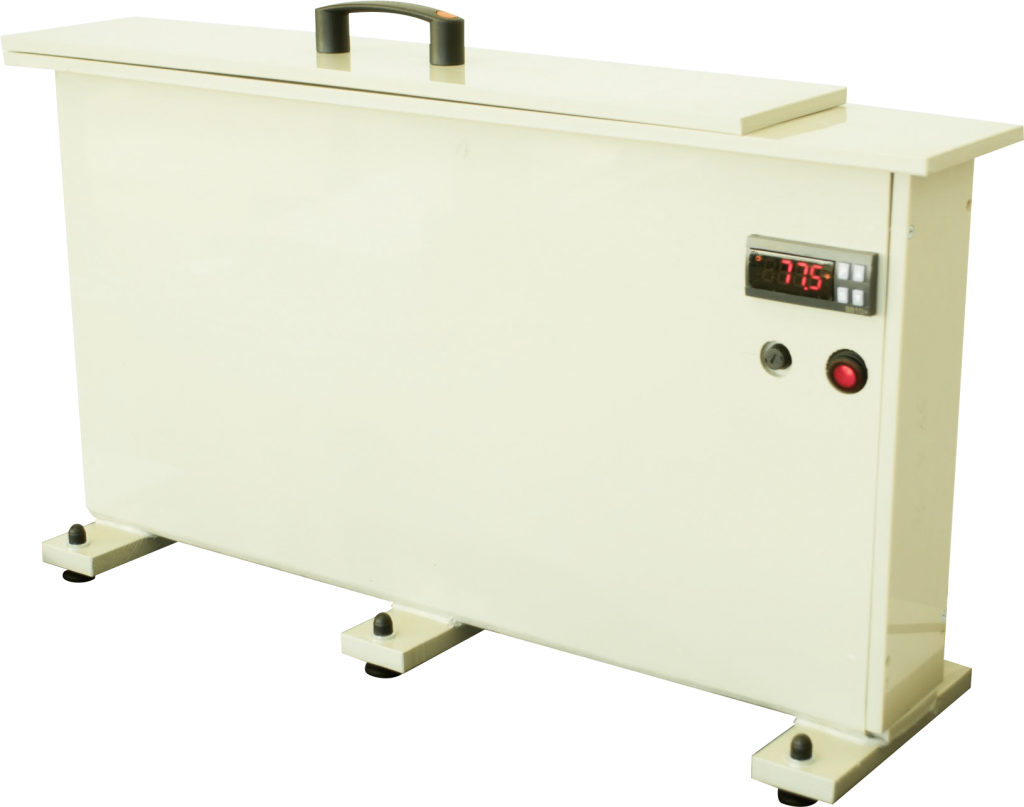

Processing bath – An essential component in the anodized aluminum printing process

Processing bath

Printing in anodized aluminum is used to create even indestructible designs for warehouse labels, signage, control panels or diplomas and certificates. The entire process requires a process bath to fix and seal the sheet metal. As a result, the finished product gains a protective surface of aluminum oxides, which gives it resistance to adverse weather conditions, scratches and chemical agents.

Compatible with:

Printing in anodized aluminum – benefits for your business

The full technology package for printing in anodized aluminum is easy to use and inexpensive to operate.

Printing in aluminum is characterized by very high durability and resistance to external factors. The finished 10 x 15 cm plate can be printed in 2 minutes, and its total cost is only 0,7€.

Technical specifications

Processing bath to Falco Aluminum

| External dimensions | 45,7 cm x 21,5 cm x 72,5 cm |

| Maximum sheet dimensions | 23 cm x 56 cm |

| Number of slots for sheets | 5 |

| Time required for sealing | 20-25min |

| Power Consumption | 2000 W |

Processing bath to Aquila Aluminium

| External dimensions | 56,3 cm x 21,5 cm x 87,5 cm |

| Maximum sheet dimensions | 23 cm x 56 cm |

| Number of slots for sheets | 5 |

| Time required for sealing | 20-25min |

| Power Consumption | 2000 W |

Process bath

Contact us and discover the full possibilities of printing in anodized aluminum using a technology bath.

Order Processing Bath

Accessories Processing bath